The ZLG series vibrating fluidized bed dryer is widely used for drying, cooling, and humidifying powder and granular materials in industries such as chemical, light industry, pharmaceutical, food, plastics, grain and oil, slag, salt production, and sugar.

Ordinary fluidized bed dryers may have the following problems when drying granular materials: (1) when the particle size is small, it may form channel flow or dead zone; (2) When the particle distribution range is large, entrainment will be quite severe; (3) Due to the backmixing of particles, the retention time of materials in the machine varies, resulting in uneven moisture content of dried particles; (4) When the humidity of the material is slightly high, agglomeration and agglomeration phenomena may occur, leading to deterioration of fluidization. In order to overcome the above problems, several modified fluidized beds have emerged, among which the vibrating fluidized bed is a relatively successful modified fluidized bed dryer.

Vibration fluidized bed is the application of mechanical vibration to the fluidized bed. Adjust the vibration parameters to achieve ideal piston flow in a regular fluidized bed with severe backmixing during continuous operation. Meanwhile, due to the introduction of vibration, the above-mentioned problems of ordinary fluidized beds will be significantly improved.

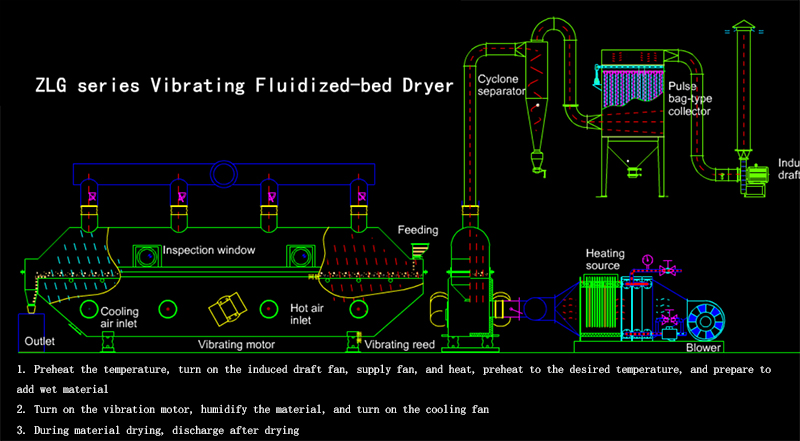

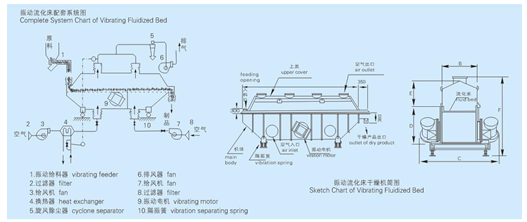

The material enters the machine from the feed inlet, and under the action of vibration force, the material is thrown along the horizontal fluidized bed, continuously moving forward. The hot air passes through the fluidized bed and exchanges heat with the wet material. The wet air is removed by the cyclone separator and discharged by the exhaust air ratio of 1:3. The dry material is discharged from the discharge inlet.

1. The vibration source is driven by a vibration motor, which runs smoothly, is easy to maintain, has low noise, and has a long service life.

2. Fluidization is uniform, without dead gaps or blow through phenomena, which can achieve uniform drying and cooling of products.

3. Good adjustability and wide applicability. The thickness of the material layer, the speed of movement inside the machine, and the full amplitude can be infinitely adjusted.

4. The damage to the surface of the material is minimal. It can be used for drying fragile materials and does not affect the working effect even when the material particles are irregular.

5. Adopting a fully enclosed structure effectively prevents cross infection between materials and air, ensuring a clean working environment.

6. High mechanical and thermal efficiency, good energy-saving effect, can save 30-60% energy compared to general drying devices.

Suitable for drying, cooling, and other operations of powdered and granular materials in industries such as chemical, pharmaceutical, food, dehydrated vegetables, grains, and minerals. For example: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, radish, silk, soybean meal, distiller's grains, seeds, slag, sugar, etc.

Previous:RDSZ Series Rotary Flash Dryer